Why students order last minute assistance with assignments from us

You have the flexibility to chose an assignment expert that suits your budget and quality parameters. We have more than 2000 PhD experts available to assist with assignments.

-

Order Preview Before Final Work

You get a preview before making final payment.

-

Pay Using different channels

You can pay using multiple secure channels, such as PayPal or Credit Cards.

-

Plagiarism Free Work Guaranteed

We sent unique content with no plagiarism.

-

Ping Us On Live Chat

You can talk to us anytime around the clock. We are up for the support.

-

Choose Your Own Expert

We let you chose from the pool of 2000 PhDs tutors.

-

Go Mobile

You do not need to be on laptop all the time, our mobile interface is great to use.

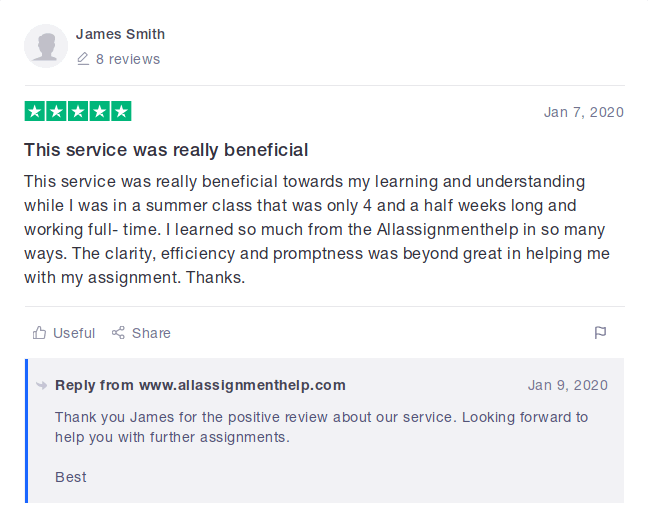

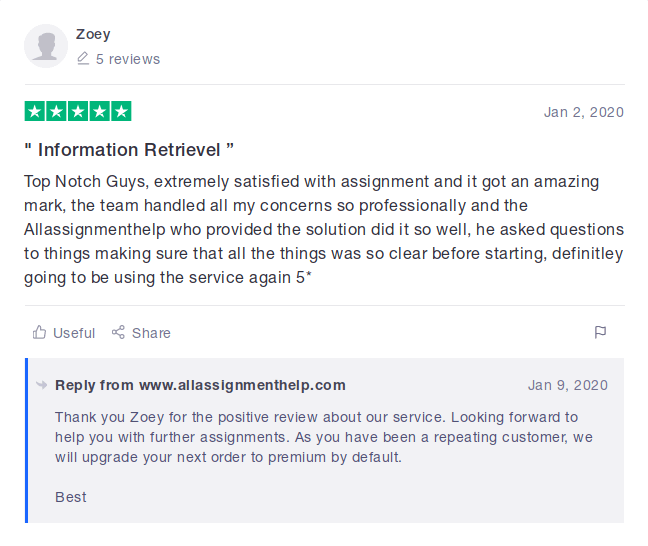

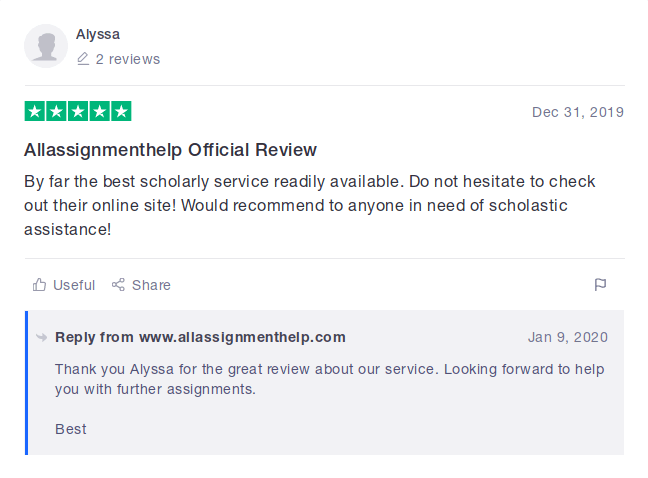

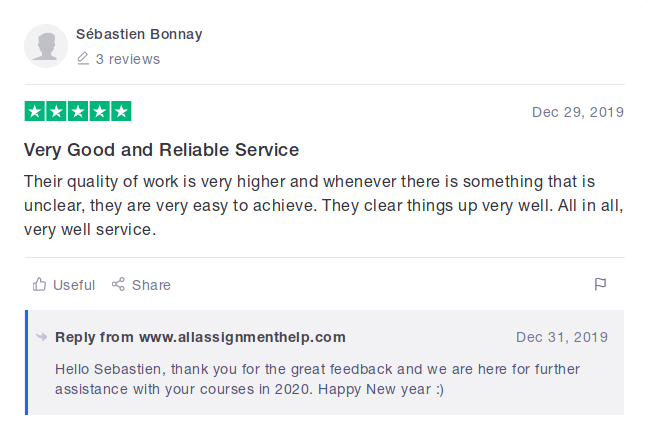

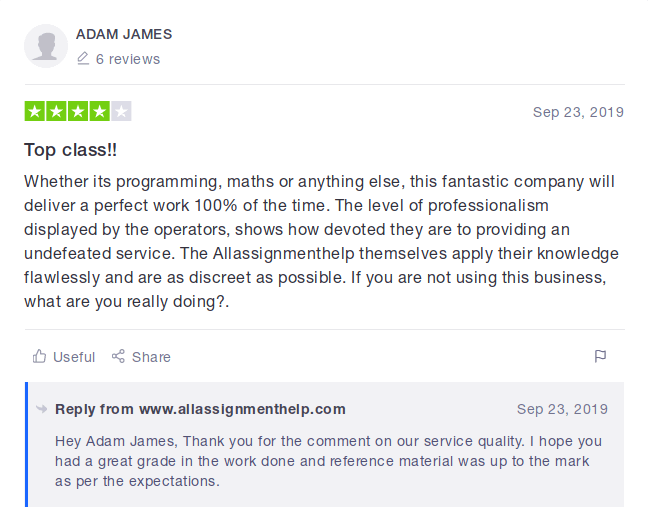

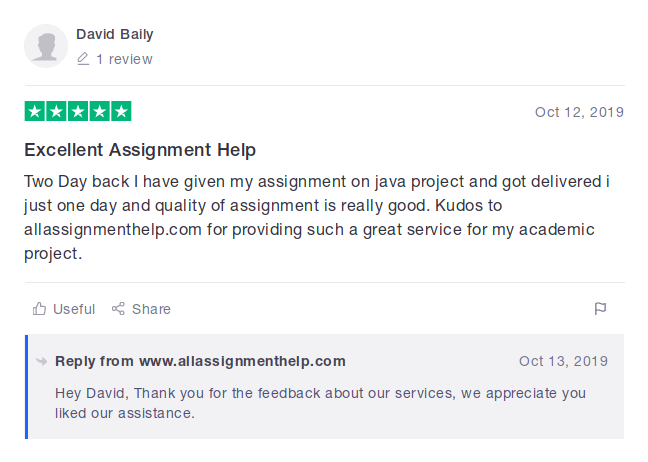

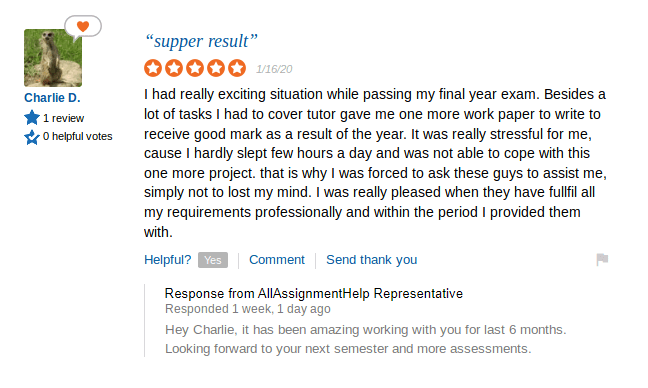

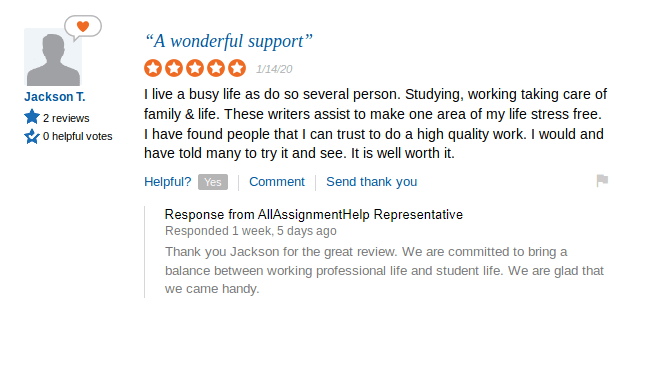

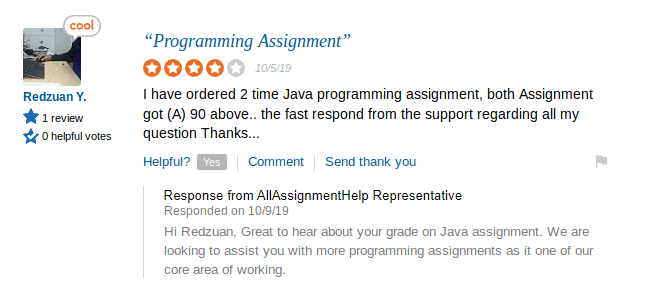

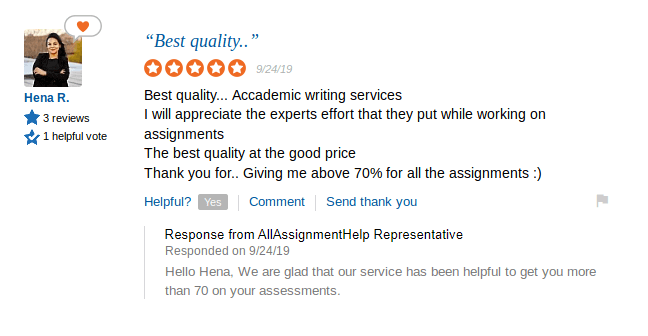

Reviews and Trust Go Hand In Hand

Allassignmenthelp.com has garnered nothing but praise from the clients. Any trustworthy review platform has positive review about our service and gives us motivation to improve.

Claim Your Offer

30% OFF & 150% Cashback on your First order !

Type your whatsapp number to get an exclusive code.

Recent Completed Projects

You can look at some of the samples that we did recently, we strongly recommend not to use samples for writing your assignment.

Thinking of where to avail pocket friendly services?

Save your money and time with us.

Place Your OrderUse of Chemicals in daily life

Chemicals form a very important part of our daily life. They are present everywhere, from what we eat, to what we wear and where we live; chemicals are omnipresent. Due to advancement in science and technology, the usage of chemicals has become a lot more than what it was in the past. The invention of plastics has been one of the most useful evolution in the chemical industry. It is originally made from crude oil. Plastic has replaced wood, metal, steel and even cloth when it comes to shopping bags.

Food preservatives involve a number of different chemicals. These chemicals help to increase the shelf life of food without degrading its quality. Food packaging materials also contain chemicals. Insecticides, pesticides and fertilizers enable healthy and quick growth of crops by protecting them from insects and acting as manure to the soil.

Chemicals are used for cleaning purposes too. Detergents are made from surfactant. This chemical helps to reduce the tension of water. It helps to mix water with oil, which is the reason why we use detergent to wash dirty clothes. Shampoos also have some portion of detergent in their composition. This helps to clean hair easily by removing dirt and oil. Toothpastes contain chemicals like aluminium hydroxide, calcium carbonate and sodium fluoride. These chemicals act like germ resistors and strengthens enamel.

Chemical processes are also involved in transforming textile raw materials into finished clothes. These chemicals help to increase the strength of the fabric and make them wrinkle less. Chemicals are also widely used in printing, dyeing and improving the quality of fabrics. Perfumes and air fresheners are also made from chemicals. These chemicals vaporize easily, hence perfumes are kept in a bottle(Health and Safety Committee, 2008).

Legislations related to chemical management in Malaysia

| Category | Agency | Relevant Legislation |

|---|---|---|

| Pesticides | Pesticides Board | Pesticides Act 1974 |

| Industrial Chemicals | Ministry of Health, Pharmaceuticals Services Division | Poisons Act 1952 |

| Drugs | Ministry of Health, Pharmaceuticals Services Division | Poisons Act 1952 |

| FoodFoodFood | Food Safety and Quality Division | Food Act 1983 |

| Emission to water, air and soil | Department of Environment | Environment Quality Act 1974 |

| Pesticides Residue in Food | Food Safety and Quality division | Food Regulations 1985 |

| Workers Health and Safety | Department of Occupational Health and Safety | Occupational Safety and Health Act 1974 |

| Cosmetics | Pharmaceuticals Services Division | Control of Drugs and Cosmetics Regulations 1984 |

Effects of chemicals on Human Health

Workers working in Malaysian Oil Palm plantations have revealed the truth about how the working conditions have been affecting their health. Workers have complained that the pesticides given to them are causing irritation to their skin and eyes. These side effects have degraded their potential to work efficiently.These pesticides have had a vulnerable effect on women too. Women are more sensitive to exposure to these chemicals(Quek, 2016). Many pregnant women have complained that the chemicals prove to be toxic to the foetus and hence their pregnancy has become more complicated.Long term exposure to chemicals have caused Malaysian workers a lot of physical and mental damage. Some of the chronic diseases caused by these chemicals include cancer, hormonal disruption and future fertility of individuals(Abdullah, Sulaiman, & Rahim, 2016).

Bauxite mining in Malaysia has caused destruction of habitats and deprived human beings of clean water, air, and soil. The polluted ecosystems have huge potential to cause health problems to people residing in that area. The Lynas Advanced Materials plant in Malaysia is dumping a large amount of toxic material in the environment. One of the most dangerous chemical in this plant is the Thorium by-product. Thorium is causing risk of cancer in many workers at the plant who are exposed to it. Also traces of thorium in the air have proven to be causing lung cancer and cancer of the pancreas(Rengam, 2008).

"I guess I have found the right place where I can rely for my assignments. I had to complete an English assignment a few days back, and the deadline was near. I came across this website, and my life took a turn. They offer discounts which are genuine and also the quality is of top notch. My assignment reached to me before the deadline. Thanks guys."

Liza M.,

Malaysia

Chemical Management System

In this section, a detailed plan to manage two different categories of chemicals is stated. It involves steps to be taken regarding receiving, storing, using and disposing these chemicals safely. This is also known as the cradle to grave management plan. The first category of chemical is Flammable Chemicals. These chemicals catch fire very quickly and pose a heavy threat if not taken care of carefully.

Flammable chemicals

Receiving

In order to receive corrosive chemicals with safety, the shipment of containers should be carefully checked for any kind of leakage. Once received, the quantity and date of receiving should be duly noted. The acids and bases should be separated in order to ensure appropriate storage. The inventory should be kept updated and clear hazard warnings should be labelled to make the workers aware of the potential risks the chemical could cause. Proper maintenance of inventory also helps in case of emergency situations. A committee should be formed that records the introduction of any new category of chemicals inthe workplace. The inventory should be revised at regular intervals in order to discard any out of date or unwanted chemicals. The emergency numbers should be clearly displayed in factories. Also, a proper cleaning staff and equipment should be maintained to make sure that in case of spillage while receiving chemicals, nobody gets hurt. The labels should be immediately replaced in case of damage. In case the received chemicals do not have labels, the manufacturer should be immediately contacted to gather correct information about the product. In addition to the manufacturers' labels, the factory should also put its own distinguished labels for the convenience of workers.

Storage

While storing flammable or combustible chemicals the following precautions should be taken:

- These chemicals should be kept at a healthy distance from all kinds of ignition sources like direct sunlight, spark and open flames.

- Flammable chemicals should be separated from other hazard causing chemicals like toxic, explosives and oxidizers.

- A minimum distance of 20 feet should be there between flammable gases and oxidizing gases and should be separated by a non-combustible partition(Foo, 2015).

- A fire extinguisher should be kept readily available and the concerned person should be well trained how to use it in case of emergency.

- In places where there are chances that static electricity could accumulate flammable vapors, flammable liquid containers should be grounded and bonded.

- Flammable liquids that require cold storage should be stored in laboratory safe flammable freezers to avoid chances of fire.

- Non-laboratory safe freezers or refrigerators are prohibited to be used for storing flammable.

Transfer

While transferring flammable and combustible chemicals, extra care has to be taken. Only one container should be dispensed at a time. Containers should be tightly closed after transferring chemicals to avoid spillage and control hazardous vapors. Use transfer pumps that are safety approved by the authorities. To ensure proper working of devices, they should be checked frequently. This eliminates the chances of using faulty machinery that may cause leaks. Flammable liquids should never be transferred near ignition sources. Metal containers should always be bonded and grounded while dispensing. Do not pressurize usual shipping containers with air to transfer liquids. This pressure can damage the original drums and create a flammable environment in the containers. The dispensing areas should be clearly marked with warning signs(DOSH, 2014).

Handling

Handling and using flammable liquids in the workplace can expose people to numerous hazards. A safety program should be designed to minimize the risk of fire from this category of chemicals. While using flammable chemicals, the area should be free from any source of heat that could possibly ignite the chemical. A separate area should be allotted at work to use these chemicals. In addition, not only should the area be clear from external igniting sources, but also from other chemicals present in the factory like oxidized gases. Proper training should be given to personnel who will be using these chemicals to make them aware about the potential hazards and the ways to avoid and combat them(RIL, 2012). Proper equipment should be used to handle these chemicals to reduce the chances of spillage that could further cause accidents.

Place Order For A Top Grade Assignment Now

We have some amazing discount offers running for the students

Place Your OrderDisposal Precautions

Disposing flammable chemicals also require careful steps which can be stated as follows:

- No flammable chemical should be poured down the sewerage pipelines.

- Flammable liquids to be disposed should be collected in appropriate glass, metal or plastic containers.

- Label the containers carefully with detailed information to avoid confusion.

- All the containers should be kept closed to avoid contact with the external environment.

- Once the container is full it should be put in the designated collecting area to be picked up(California, 2010).

Corrosive Chemicals

The second category of chemical is Corrosive Chemicals. These chemicals include strong acids and bases. They can destroy human skin and metals.

Receiving

The steps to be taken while receiving chemicals is the same in case of all categories. There are some common measures to be taken in order to safely receive the chemicals at work place. Making proper records of the type of chemical and the quantity received. The inventory should be up-to-date and clearly stated with the possible hazards they can cause. This eventually helps to store these chemicals safely. An accurate record is also useful in case of emergency where firemen or other emergency responders are to combat a fire or chemical release carefully. There should be strict rules against factories which fail to maintain proper record of their inventory. The concerned authority should be informed if a new category of chemical is being introduced. The inventory should be revised every year in order to get rid of unwanted chemicals at work place as hey can pose threat to the safety of the work place as well as workers. All hazardous chemicals should be clearly labelled for both current and future users(Department of Environmental Health and Safety, 2017). Damaged or missing labels should be immediately replaced. The manufacturer should be asked to provide information like contents in the container, physical hazard information and emergency number of contacts. In addition to the manufacturers’ labels, the factory should also put their own labels.

Storage

In order to safely store corrosive chemicals, following precautions to be taken:

- While storing corrosive chemicals, the acids should be separated from the bases as they can react.

- Inorganic oxidizing acids like nitric acid should be stored away from flammable chemicals and organic acids.

- Tight fitted gloves, goggles and shoes should be worn wile storing these chemicals.

- Corrosives should be stored on lower shelves, mostly below eye level.

- These chemicals should not be stored on metal shelves.

- If powder deposits, crystallization or discoloration is noticed the emergency department should be contacted as the material could be potentially explosive.

- The storage area should be well ventilated and equipped with firefighting and clean up equipments(EFSA, 2017).

- The area should not be prone to rapid temperature changes.

Transfer

When transferring corrosive chemicals, extra care should be taken as the human skin and tissue can get tremendously destroyed if it comes in contact with these chemicals. The transfer should be usually done from small to large containers to avoid spillage. Before transferring the containers should be properly checked for leakage. The containers should be closed properly after dispensing. A non corrosive drum and drum pump should be used to avoid corrosion of metal. Never pipette corrosive liquids by mouth. The original shipping containers should not be pressurized with air. A pipette bulb should be used for transferring these chemicals. Solid corrosives should be transferred using corrosion resistant shovels.

Handling

While using corrosive chemicals eyes should be protected. Ordinary glasses do not provide proper safety and hence safety glasses that meet proper safety guidelines should be used. These glasses should also have a side shields in case of protection from flying particles. Nitrile gloves should be worn along with a lab coat or apron. Open toe shoes should not be worn. In case of using corrosive gases, make sure that all skin surfaces are covered. Regulators and valves should be closed if the chemical is not in use. Corrosive gases should handled carefully to avoid dangerous reverse flow(Kamarulzaman, 2012).

Disposal

Corrosive wastes are highly hazardous and must be disposed safely. The containers for corrosive wastes must be made from corrosion resistant materials. The containers should be labelled properly with details of contents present. The drums or bottles left empty after disposal should be checked for any residue and the same should be removed. These containers should not be used to store anything else, no matter how clean they appear to be. Corrosives should never be disposed down the sinks. Appropriate officials should be contacted about how to dispose these chemicals without harming the environment.

Note: This is not a complete solution. You can request the complete solution by filling out the order form towards your requested assignment.

Place Order For A Top Grade Assignment Now

We have some amazing discount offers running for the students

Place Your OrderREFERENCES

Abdullah, N., Sulaiman, H., & Rahim, D. (2016, May). Potential Health Impacts of Bauxite Mining in Kuantan. PMC Journal, 23(3), 1–8. Retrieved from https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4934713/

California, B. U. (2010). Safe Storage of Hazardous Chemicals. Retrieved from https://ehs.berkeley.edu/sites/default/files/lines-of-services/hazardous-materials/chemicalstoragebooklet.pdf

Department of Environmental Health and Safety. (2017). Corrosive Chemicals: What Is the Scope of This Guideline? Retrieved from https://www.brandeis.edu/ehs/labs/corrosives.html

DOSH. (2014). Chemical management division. Department of Occupational Safety & Health Malaysia. Retrieved from https://www.dosh.gov.my/index.php/en/list-of-documents/osh-info/chemical-management-1/promotional-materials/2262-chemical-management-division-function-brochure/file

EFSA. (2017). Chemicals in food. Retrieved from https://www.efsa.europa.eu/en/topics/topic/chemicals-food

Foo, C. (2015, November). The Malaysian Chemicals Industry: From Commodities to Manufacturing. Retrieved from https://www.aiche.org/resources/publications/cep/2015/november/malaysian-chemicals-industry-commodities-manufacturing

Health and Safety Committee. (2008). Procedure for the storage and handling of fuel of construction sites. IHSA. Retrieved from https://www.ihsa.ca/pdfs/research_docs/fuel_handling_procedure.pdf

+1-817-968-5551

+1-817-968-5551 +61-488-839-671

+61-488-839-671 +44-7480-542904

+44-7480-542904